Skip to content

100% NETT Weight Control

Equipment > Capsule Fillers > Check Weighing for Capsule Fillers > 100% NETT Weight Control

100% NETT Weight Control

- 100% in-process control system integrated into the machine.

- Monitors and controls the “net” weight of each filled capsule and automatically rejects any single capsule which is found to be outside the weight limits.

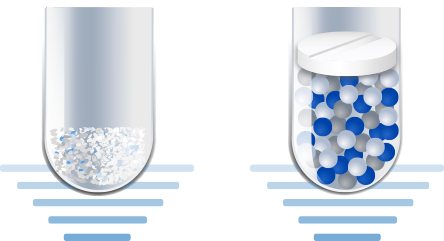

- Uses two capacitive sensors to first check the empty capsule and subsequently the same capsule after filling to calculate the net weight of the product dosed by subtracting one from the other.

- The two sensors are automatically and continuously calibrated throughout the production run. The system computer checks & manages all the data collected by the sensors and the balance and automatically makes adjustments in capsule fill weight.

- Monitors the performance of individual dosators.

- Complete analysis of production batch including batch reports.

admin2022-03-07T21:19:45+00:00